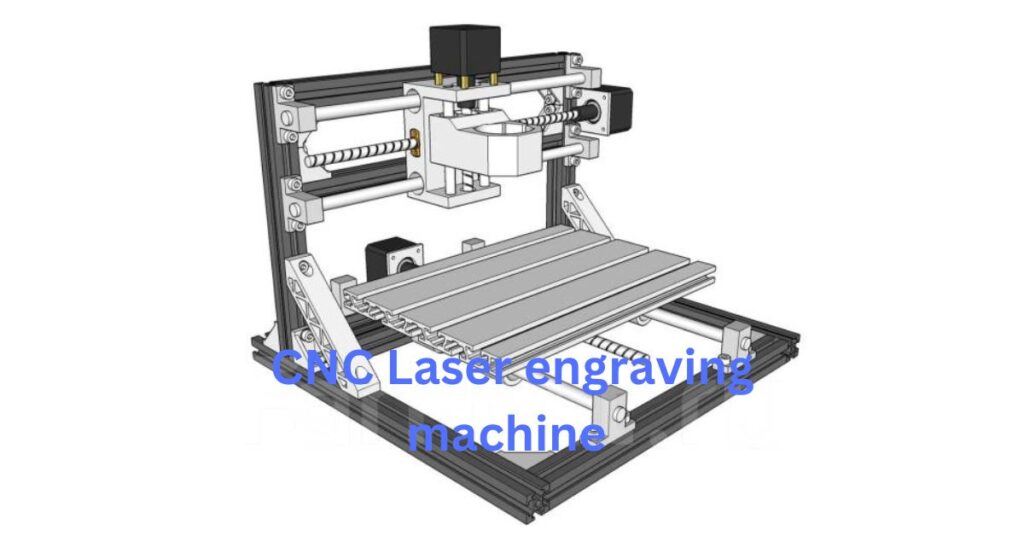

CNC, or PC Mathematical Control, denotes that a machine is being constrained by computer software. It makes engraving precise possible. Moreover, the ability to repeatedly and precisely duplicate designs.

CNC laser engraving equipment is frequently used in the commercial, sign-making, and arts and crafts sectors to add detail. Its features amazing patterns for glass, metal, plastic, and wood, among other materials.

CNC laser etching machines come in a variety of models, each with special features and functionalities. Certain machines are made to work with bigger materials, while others are simpler and more appropriate for smaller-scale tasks. Furthermore, certain machines are more appropriate than others for etching on a larger range of substrates.

How Does a CNC Laser Engraver Operate?

It starts the work with a digital design file (CAD/CAM ) that is uploaded through the CNC software .This work as translator and command the machine for work and guide to the laser head for action .Here’s to clarify the collapse and how it operates.

Planning : First of all, the user creates the important design on it .

Laser Tuning :Then adjust the power,speed ,and arrange the material based .

Engraving action: CNC system directs the Stimulated Emission on meterial ‘s surface level designs based on .

Complete work : It creates the design and product the polishing if needed .

Engraving Machine for Metal

When selecting a CNC laser etching machine for metal, there are a few important considerations to make. Here are some key components:

The speed at which the CNC laser can examine the metal is a crucial factor to take into account as it has the potential to impact both completion time and production.

Reliability: In metal engraving , the machine’s clarity and accuracy should be pivotal. Find a machine with a high goal that can produce complex designs with almost no deviations.

Size: Depending on the dimensions of the workspace of the CNC laser engraving machine, the largest size of the metal objects that can be etched will vary.

Material compatibility: Verify that the etching machine is compatible with the metal kinds you intend to use. For example, certain metals may require the use of particular types or frequencies of lasers.

How Does a CNC Laser Engraver Operate?

It starts the work with a digital design file (CAD/CAM ) that is uploaded through the CNC software .This work as translator and command the machine for work and guide to the laser head for action .Here’s to clarify the collapse and how it operates.

Planning : First of all, the user creates the important design on it .

Laser Tuning :Then adjust the power,speed ,and arrange the material based .

Engraving action: CNC system directs the Stimulated Emission on meterial ‘s surface level designs based on .

Complete work : It creates the design and product the polishing if needed .

Material that are Best for Laser Engraving

CNC Machines are veriable and work at a broad level with different meterials .

Matel

In metal include stainless steel ,Copper ,Brass aluminium and with copper it works and creates the design of different kinds .

Wood

Plywood ,MDF ,and on the bamboo it works

Plastic

CNS Machine works on plexiglass , ABS, polycarbonate for different designing

It works on Glass and ceramic

CNC machine create different design on Leather and fabrics

Benefits of Engraving machine

It has different advantages to make the several design on different materials

- It can create complex designs on different stuff with high accuracy .

- It speeds and plans very fast and cuts and engraves the traditional method .

- It creates permanent design and durable marking with strength.

- Its creativity is that it works on a variety of materials.

- It is ideal for collection of production and pack engraving .

How Many Metal Engraving Tools?

The amount of tools needed for metal engraving and etching might vary depending on the demands and preferences of the etcher. Nonetheless, gravers, bruces, etches, sleds, recorders, and cleaning tools are among the often used metal etching tools.

Punches and texturing tools are examples of certain tools that others may use for predetermined strategies or goals. Depending on their level of expertise, metal engravers may use fewer or more tools. So this explains the intricacy of their schemes and the metals they employ.

Scribes: Scribes are sharp devices employed to inspect metal lines before to etching.

Enhancing focal points: Etching usually calls for a close examination, therefore it may be very beneficial for identifying small details.

Tight clamps: A tight clamp can be used to hold a piece of metal firmly in place while it is being engraved.

Power tools: To expedite the etching process or produce specific effects such as some others use power tools like drills or pneumatic etching systems.

Tools and techniques: Again, an etcher’s particular tools and procedures vary depending on the type of metal they are working with, their approach, and their style.

How to Utilize a Laser Etching Machine?

Make the strategy: Using a computer, create or import the plan you want to imprint on the material. So this verify that the plan is appropriately sized and positioned for the material you intend to imprint.

Put the device together: After placing the material firmly on the etching table, move the laser’s focus point to the right so that it is away from the material’s outer layer. The best way to accomplish this should be covered in the instructions that come with the laser etching equipment. This will entail choosing the laser’s power, rate of change, and other significant parameters.

Establish the settings: Adjust the laser etching machine’s settings according to the material you want to imprint on. Selecting the laser’s power, speed, and other settings that influence the etching will be necessary for this.

Control board of the machine: Use the control board of the machine or preprogrammed instructions to begin the etching operation. The laser will follow the plan and etch the design onto the material.

After the etching is finished, take the material off of the etching table and examine the composition of the etching. After making changes to the parameters, repeat the cycle for the important event.

It’s crucial to remember that certain laser etching machinery may have particular developments or needs for operation. It is important to read the manufacturer’s instructions and take all necessary safety precautions before using a laser etching machine.

CNC Laser Engraving Machine Price in Pakistan

The gadget can cost as much as PKR 250,000.

It’s crucial to remember that there are other costs to take into account besides the machine’s price. Possible additional costs include shipping, taxes, and any necessary maintenance or adjustments. It’s important to consider the cost of any software and any training needed to operate the equipment.

It is advisable to research and compare different CNC laser engraving machines and providers in Pakistan to select a machine that fits your needs and budget.

For more info : Engraver Marker Engraving Rotary jewelry Ring Firearms